- Email: info@silkroadabrasives.com

White Fused Alumina Micro Powder Product Details Product OverviewWhite Fused Alumina Micro Powder is a high-performance material produced by melting premium alumina powder at high temperatures. The production process involves melting in an electric arc furnace, cooling to form white fused alumina blocks, followed by crushing, magnetic separation, acid washing, cleaning, and drying. The final product primarily consists of α-Al2O3 crystals with a sodium content as low as0.1% or less. This low sodium content not only increases the melting point but also enhances the grain density, bulk density, flexural strength, compressive strength, true density, and hardness. White Fused Alumina Micro Powder is renowned for its dense crystal structure, high density, excellent transparency, and superior insulation properties.

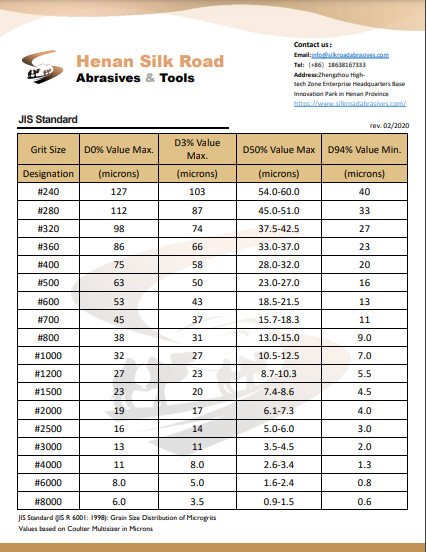

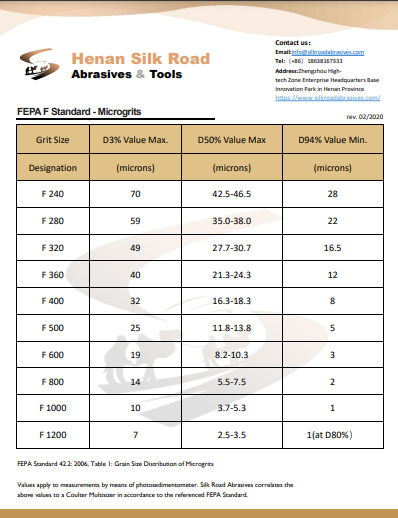

Standards ComplianceWhite Fused Alumina Micro Powder’s particle size distribution adheres to various standards to meet diverse market needs:

– JIS Standard: Predominantly used in the Asian market, emphasizing precision and consistency in particle size, suitable for high-precision applications.

– FEPA F Standard – Microgrits: Common in the European market, offering a detailed particle size range, suitable for various industrial applications.

Special Requirements and Differentiated NeedsBeyond conventional standards, we cater to specific customer requirements:

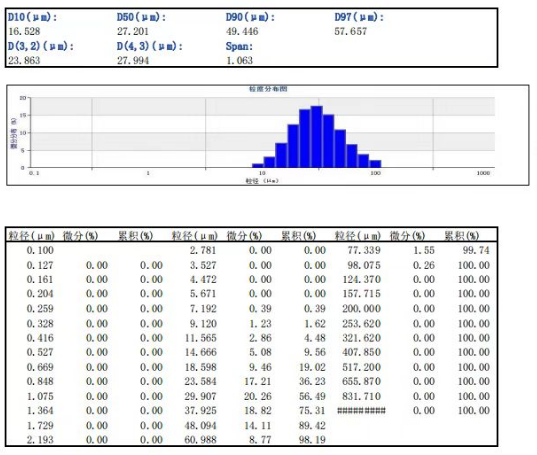

W28:

Suitable for applications requiring finer particle sizes, its uniform distribution ensures high surface finish, ideal for precision polishing and grinding processes.

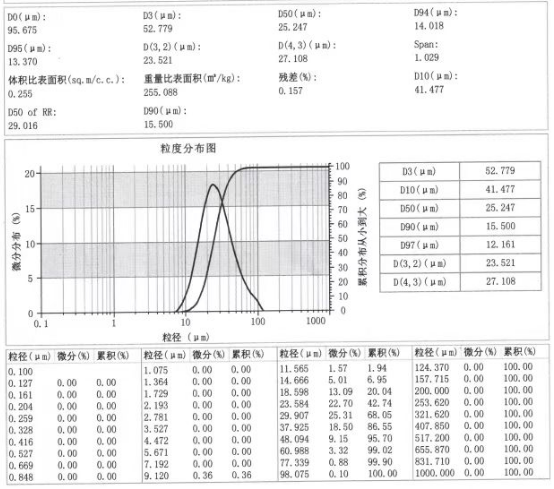

600#:

Suitable for general polishing and grinding applications, its broader particle size distribution provides excellent cutting force and wear resistance, widely used in metal processing, glass, and ceramics industries.

By comparing different particle size analyses, we gain a deeper understanding of the differences in particle distribution between W28 and600#, enabling us to offer optimal solutions based on customer application needs.

Our Advantages1. Customized Production: We offer tailored products based on specific customer needs, whether for high-precision electronic component processing or general industrial grinding.

Contact UsIf you have any inquiries or requirements regarding our products, please feel free to contact us. Our professional team is dedicated to providing you with the most suitable solutions.