- Email: info@silkroadabrasives.com

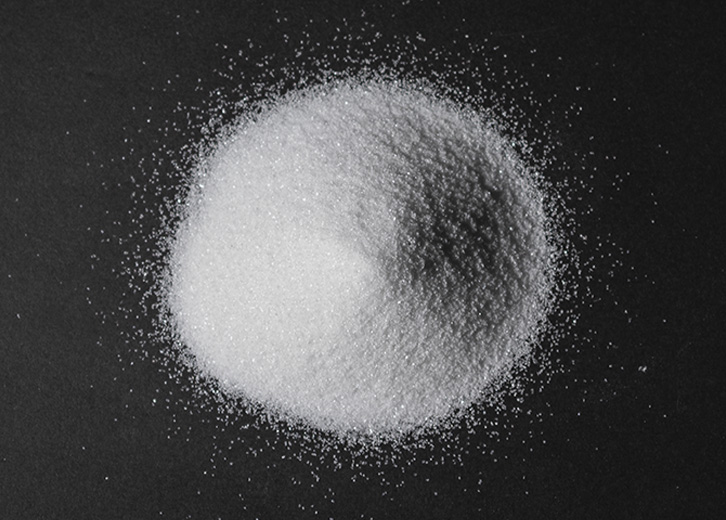

White fused alumina macro,also referred to as white fused alumina grain-size sand, are produced by refining high-quality alumina powder through the process of electromelting and meticulous sieving. These coarse grits are primarily utilized in various grinding applications, such as surface grinding, external and internal cylindrical grinding, and creep-feed grinding of low-alloy steel. They find wide-ranging industrial uses, including pressure blasting, microdermabrasion, polishing, creating anti-skid surfaces, and serving as refractory materials.

|

Physical properties |

||

|

Hardness: |

9 mohs |

|

|

Crystal Form: |

Alpha - Alumina |

|

|

Melting point: |

2250°C |

|

|

True Density: |

3.95g/cm3 |

|

|

Color: |

White |

|

|

Bulk density: |

depending on grain size |

|

|

Typical chemical analysis |

|

|

Al2O3: |

99.63% |

|

Fe2O3: |

0.06% |

|

SiO2: |

0.09% |

|

Na2O: |

0.16% |

|

Available grain sizes (Average grain size) |

|

|

FEPA Nr |

Granulometry |

|

F 012: |

1400–2000µm |

|

F 014: |

1180–1700µm |

|

F 016: |

1000–1400µm |

|

F 020: |

850–1180µm |

|

F 022: |

710–1000µm |

|

F 024: |

600–850µm |

|

F 030: |

500–710µm |

|

F 036: |

425–600µm |

|

F 040: |

355–500µm |

|

F 046: |

300–425µm |

|

F 054: |

250–355µm |

|

F 060: |

212–300µm |

|

F 070: |

180–250µm |

|

F 080: |

150–212µm |

|

F 090: |

125–180µm |

|

F 100: |

106–150µm |

|

F 120: |

90–125µm |

|

F 150: |

63–106µm |

|

F 180: |

63–90µm |

|

F 220: |

53–75µm |

Removes oxidation layers and contaminants from metal surfaces, improving the quality and precision of parts.

Used for precision polishing and refinement of ceramic products.

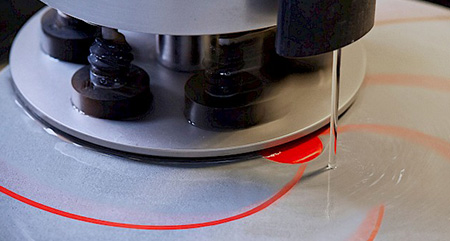

Removes scratches and imperfections from glass surfaces, enhancing their texture and luster.

Removes oxidation layers and contaminants from automotive parts, enhancing their quality and appearance.

Removes oxide layers and contaminants from electronic component surfaces, improving their performance and reliability.