- Email: info@silkroadabrasives.com

Silk Road Abrasives’ Green Silicon Carbide is created from high-purity quartz sand and coke in an electric resistance furnace. It’s processed through ultra-fine grinding and classification to form micro-powders. With a greenish transparent color and a hexagonal α-type crystal structure, it boasts remarkable hardness, just below diamond. Its strong cutting ability and stable chemical properties make it ideal for grinding hard, brittle, and non-metallic materials like hard alloys, optical glass, ceramics, semiconductors, and more. Our Green Silicon Carbide particles and powders undergo diverse techniques to optimize their shape, surface, and density.

| Physical properties | |

| Crystal Form: | Hexagonal (Alpha SiC |

| Color: | Green |

| Melting point: | Dissociates at Approx. 2500°C |

| True Density: | 3.21 g/cm3 |

| Hardness: | Knoop (100): 2500 Mohs: 9.0+ |

| Bulk density: | depending on grain size |

| Typical chemical analysis | |

| Silicon Carbide (SiC) | 99.25% |

| Free Carbon (C) | 0.05% |

| Silicon Dioxide (SiO2 ) | 0.35% |

| Free Silicon (Si) | 0.15% |

| Iron (Fe2 O3 ) | 0.04% |

| Available grain sizes | |||||

| (Average grain size) | |||||

| ds50 value (µm) | |||||

| FEPA Nr. | Standard werte der Mikro-F-Reihe | JIS Nr. | FEPA Nr. | ||

| F230 | 53±3.0 | #240 | 60±4.0 | P240 | 58.5±2.0 |

| F240 | 44.5±2.0 | #280 | 52±3.0 | P280 | 52.2±2.0 |

| F280 | 36.5±1.5 | #320 | 46±2.5 | P320 | 46.2±1.5 |

| F320 | 29.2±1.5 | #360 | 40±2.0 | P360 | 40.5±1.5 |

| F360 | 22.8±1.5 | #400 | 34±2.0 | P400 | 35.0±1.5 |

| F400 | 17.3±1.0 | #500 | 28±2.0 | P500 | 30.2±1.5 |

| F500 | 12.8±1.0 | #600 | 24±1.5 | P600 | 25.8±1.0 |

| F600 | 9.3±1.0 | #700 | 21±1.3 | P800 | 21.8±1.0 |

| F800 | 6.5±1.0 | #800 | 18±1.0 | P1000 | 18.3±1.0 |

| F1000 | 4.5±0.8 | #1000 | 15.5±1.0 | P1200 | 15.3±1.0 |

| F1200 | 3.1±0.5 | #1200 | 13.0±1.0 | ||

| F1500 | 2.0±0.4 | #1500 | 10.5±1.0 | ||

| #2000 | 8.5±0.7 | ||||

| #2500 | 7.0±0.7 | ||||

| #3000 | 5.7±0.5 | ||||

| Other grain sizes can be customized and produced according to customer requirements. | |||||

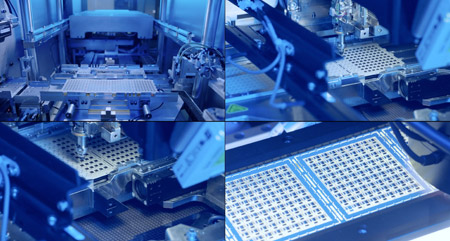

This includes cutting, polishing, etching, chemical mechanical polishing, and packaging. Its exceptional hardness, cutting performance, and thermal conductivity make it a vital tool for achieving high-precision, high-performance semiconductor devices.

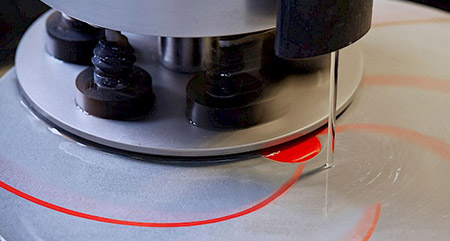

Cutting and precision grinding materials for ceramics, hard alloys, new materials, and more.

Employed in cutting, carving, polishing, and finishing agate and other non-metal gemstones, enhancing their beauty and value.