- Email: info@silkroadabrasives.com

Silk Road Abrasives’ Green Silicon Carbide is manufactured using high-purity quartz sand and coke as primary raw materials in an electric resistance furnace. It exhibits a greenish translucent color and features a hexagonal crystal structure of the α-type, boasting exceptional hardness second only to diamond. With strong cutting capabilities and stable chemical properties, it is well-suited for grinding hard, brittle, and non-metallic materials such as hard alloys, optical glass, and ceramics. The Green Silicon Carbide particles and powders from Silk Road Abrasives are produced using a variety of techniques to optimize their shape, surface area, and density.

| Physical properties | |

| Crystal Form: | Hexagonal (Alpha SiC |

| Color: | Green |

| Melting point: | Dissociates at Approx. 2500°C |

| True Density: | 3.21 g/cm3 |

| Hardness: | Knoop (100): 2500 Mohs: 9.0+ |

| Bulk density: | depending on grain size |

| Typical chemical analysis | |

| Silicon Carbide (SiC) | 99.20% |

| Free Carbon (C) | 0.05% |

| Silicon Dioxide (SiO2 ) | 0.40% |

| Free Silicon (Si) | 0.15% |

| Iron (Fe2 O3 ) | 0.04% |

| Available grain sizes | |

| (Average grain size) | |

| FEPA Nr | Granulometry |

| in µm | |

| F 012: | 1400–2000µm |

| F 014: | 1180–1700µm |

| F 016: | 1000–1400µm |

| F 020: | 850–1180µm |

| F 022: | 710–1000µm |

| F 024: | 600–850µm |

| F 030: | 500–710µm |

| F 036: | 425–600µm |

| F 040: | 355–500µm |

| F 046: | 300–425µm |

| F 054: | 250–355µm |

| F 060: | 212–300µm |

| F 070: | 180–250µm |

| F 080: | 150–212µm |

| F 090: | 125–180µm |

| F 100: | 106–150µm |

| F 120: | 90–125µm |

| F 150: | 63–106µm |

| F 180: | 63–90µm |

| F 220: | 53–75µm |

| Note: JIS and P Standard graded powder is available on request | |

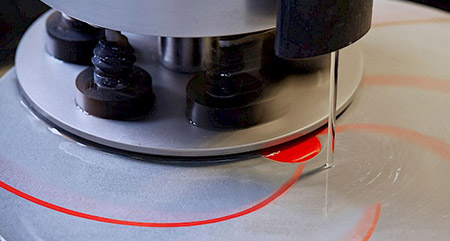

Used as material for precision grinding wheels (such as magnetic heads) and high-level polishing wheels.

Cutting and precision grinding materials for ceramics, hard alloys, new materials, and more.

Suitable for wear-resistant, refractory, and corrosion-resistant materials, also applicable in manufacturing rocket nozzles, gas turbine blades, and more.