- Email: info@silkroadabrasives.com

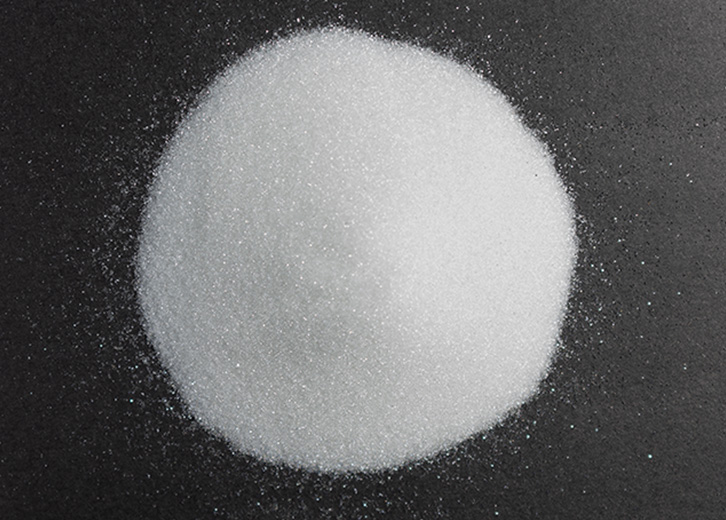

Glass beads are a commonly used media made of hardened spherical soda-lime glass. They have a uniform composition and stable chemical properties, making them ideal for cleaning, deburring, peening, and descaling. Their nearly perfect spherical shape allows for controlled and unique surface finishes. Glass beads decompose slowly, reducing equipment damage, and can withstand multiple impacts. They are chemically inert and leave no residue on workpiece surfaces.

|

Typical Physical Characteristics |

|

|

Roundness: |

≥90% |

|

Micro Hardness: |

≥600kg-mm³ |

|

Specific gravity: |

2.4–2.6 |

|

Bulk density: |

1.4–1.6 g/cm3 |

|

Typical chemical analysis |

|

|

SiO2: |

≥65% |

|

Na2O: |

≤14% |

|

CaO: |

≤8.0% |

|

MgO: |

≤2.5% |

|

Al2O3: |

0.5%-2.0% |

| Available grain sizes (Average grain size) |

|

|

Sandblasting |

20#、30#、40#、50#、60#、70#、80#、90#、100#、120#、140#、150#、170#、180#、200#、220#、240#、325# |

|

Grinding |

0.8-1mm,1-1.5mm,1.5-2mm,2-2.5mm,8.5-3mm,3.5-4mm,4-4.5mm,4-5mm, 5-6mm,6-7mm, |

|

Road Marking |

BS6088A BS6088B EN1424 EN1423 AASHTO AASHTO TYPE1 TYPEII JIS NO.1 JIS NO.2 |

Road marking for enhanced visibility and skid resistance.

Sandblasting and polishing for improved surface quality and appearance.

Filter media to improve filtration efficiency.

Paints and coatings as fillers for increased thickness, glossiness, and scratch resistance.

Pigments and dyes as carriers for even dispersion and enhanced efficiency.

such as automotive coatings, agricultural chemicals, electronic pastes, and metal oxides.