- Email: info@silkroadabrasives.com

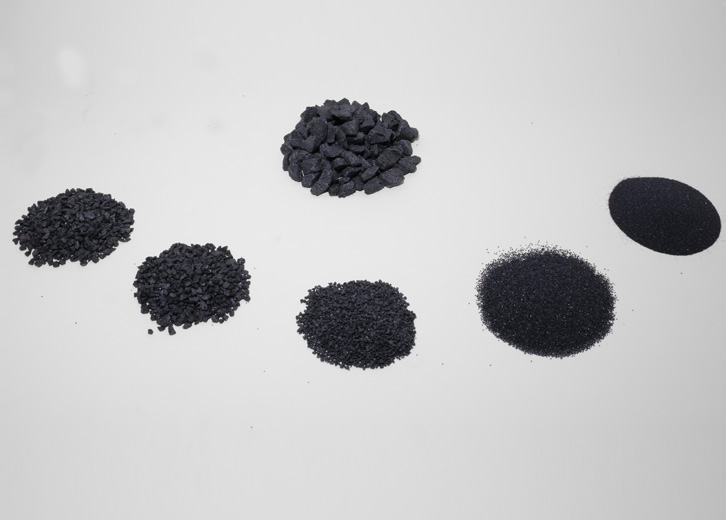

Black fused aluminum oxide is produced by smelting bauxite, iron oxide, and other elements. It offers moderate hardness, high toughness, excellent heat resistance, thermal stability, and self-sharpening. Widely used in abrasives, high-temperature processes, and wear-resistant coatings, it’s an ideal choice for diverse industrial applications.

|

Physical properties |

|

|

Crystal Form: |

Trigonal System |

|

Hardness: |

9 mohs 2000-2200 kg/mm² (Vickers) |

|

Grain shape: |

angular |

|

Melting point: |

approx. 2050°C |

|

True Density: |

≥3.50 g/cm3 |

|

Typical chemical analysis |

|||

|

|

General |

Special |

|

|

Al2O3: |

≥62% |

≥80% |

|

|

TiO2: |

2-4% |

2-4% |

|

|

Fe2O3: |

6-12% |

4-8% |

|

|

SiO2: |

≤25% |

≤10% |

|

| Available grain sizes (Average grain size) | |||

| FEPA Nr | JIS Nr | ||

| F 08 | #8 | F 90 | #120 |

| F 10 | #10 | F 100 | #150 |

| F 12 | #12 | F 120 | #180 |

| F14 | #14 | F 150 | #220 |

| F 16 | #16 | F180 | #240 |

| F 20 | #20 | F220 | #280 |

| F 22 | #24 | F230 | #320 |

| F 24 | #30 | F240 | #360 |

| F 30 | #36 | F280 | #400 |

| F 36 | #46 | F320 | #500 |

| F 40 | #54 | F360 | #600 |

| F46 | #60 | F400 | #800 |

| F 54 | #70 | F500 | #1000 |

| F 60 | #80 | F600 | #1200 |

| F 70 | #90 | F800 | #1500 |

| F 80 | #100 | F1000 | #2000 |

Black fused aluminum oxide is used for polishing metal products, especially stainless steel, to achieve a high level of surface smoothness with minimal discoloration.

Black fused aluminum oxide is utilized for grinding and polishing workpiece surfaces, providing a cutting action to remove irregularities, burrs, and scratches, and delivering a smooth and precise machining result.

Black fused aluminum oxide finds application in road abrasives for pavement repair, road surface anti-skid treatment, and other related applications.

Black fused aluminum oxide is used in various applications, including sanding belts, polishing wheels, fiber wheels, anti-skid surface materials, and more.